SENFENG AUTOMATIC SHEET METAL CUTTING, BENDING AND WELDING LINE BY IBETAMAC NEW CE

SENFENG AUTOMATIC SHEET METAL CUTTING, BENDING AND WELDING LINE BY IBETAMAC NEW CE

Contact us for price

Location:Zona L Ottavia, Italy

Description

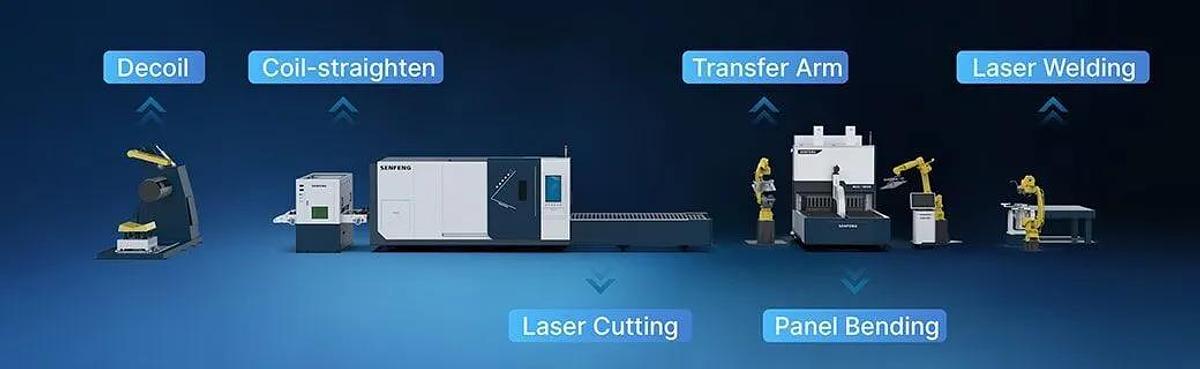

Combining cutting, bending, and welding of sheet metal coils with an automatic sorting system, TOP enables highly automated processing, from uncoiling the raw material to stacking the finished product. We also accept customizations upon request, allowing for flexible production and fast delivery times.

3000 [mm] Maximum feeding length

1500 [mm] Maximum width of the sheet metal coil

3 [mm] Maximum thickness of sheet metal coil

10 [T] Maximum weight of the sheet metal coil.

Competitive strengths

Performance Benefits

This metalworking line uses advanced manufacturing technologies and highly intelligent devices to meet the metal manufacturing industry's needs for efficient, flexible, and customized production.

1. Production in one place

Perform unrolling, cutting, bending and welding simultaneously and carry out a complete job from raw materials to finished products.

2. Increased work efficiency

Robots and other automated devices perform the entire process. Therefore, mass production will continue 24 hours a day.

3. Lower labor costs

A single worker can take control of the entire line, without any manual intervention. This helps reduce the number of workers, labor intensity, and accident rate.

4. Better finished products

Its minimal error caused by artificial factors will ensure the high quality and consistency among the finished products and minimize the scrap ratio.

Mechanical benefits

1. Safety precautions

Cameras are installed to cover the entire production line and monitor its status in real time. This way, workers are kept informed of the progress of the work even when they're standing in front of the control console.

2. Stable machine tool

* The hollow bed of the machine tool is internally unconnected, which can interrupt heat transfer, maintain high cutting accuracy and extend its service life.

* Keeps the machine tool non-deformable and intact at high temperature even after long-term use by going through 7 standard processes such as high annealing and aging treatment

3. Modular structure

We've divided the entire line into multiple modules, so users can modify its structure or add or remove specific modules based on their actual needs.

* Cutting module. Its laser cutting line combines unwinding, leveling, cutting, and unloading to achieve continuous cutting of sheet metal coils.

* Bending module. The flexible bending machine, combined with universal bending dies, is suitable for bending the same workpiece in batches.

* Welding module. The robot-assisted laser welding machine features high speed, high precision, beautiful welds, and virtually zero manual errors.

* Sorting module. The robot-assisted sorting system can complete the sorting, transfer, and stacking work.

Advantages of the control system

The entire line is subject to uniform monitoring and management through an integrated control system. This ensures that all operational procedures run smoothly.

1. Visual interface

The operating interface is easy to understand, so workers can get started quickly.

2. Intelligent management

Collect and analyze data easily and monitor all work parameters in real time.

3. High flexibility

Connect and operate all modules seamlessly

Specifications

| Manufacturer | SENFENG BY IBETAMAC |

| Year | 2026 |

| Condition | New |

| Stock Number | TPS |