MACCHINA BARRE IN RAME CNC IB 50 6 PUNZONATURA TAGLIO PIEGATURA CURVATURA

MACCHINA BARRE IN RAME CNC IB 50 6 PUNZONATURA TAGLIO PIEGATURA CURVATURA

Contattaci per il prezzo

Posizione:Zona L Ottavia, Italia

Descrizione

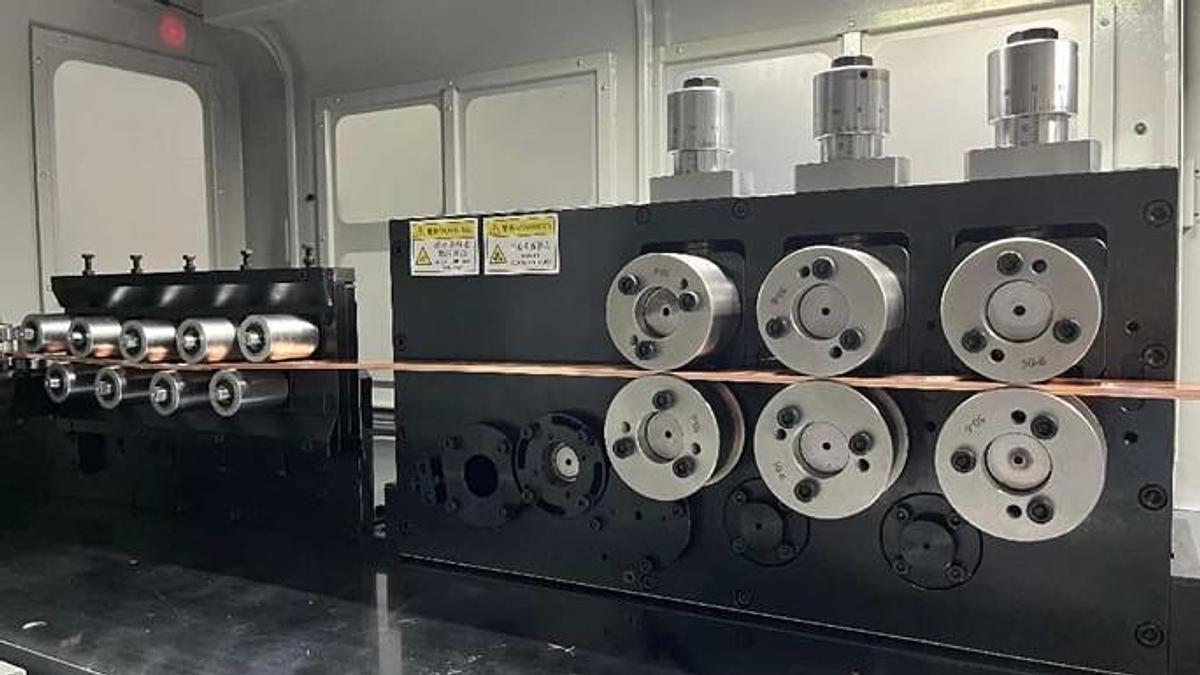

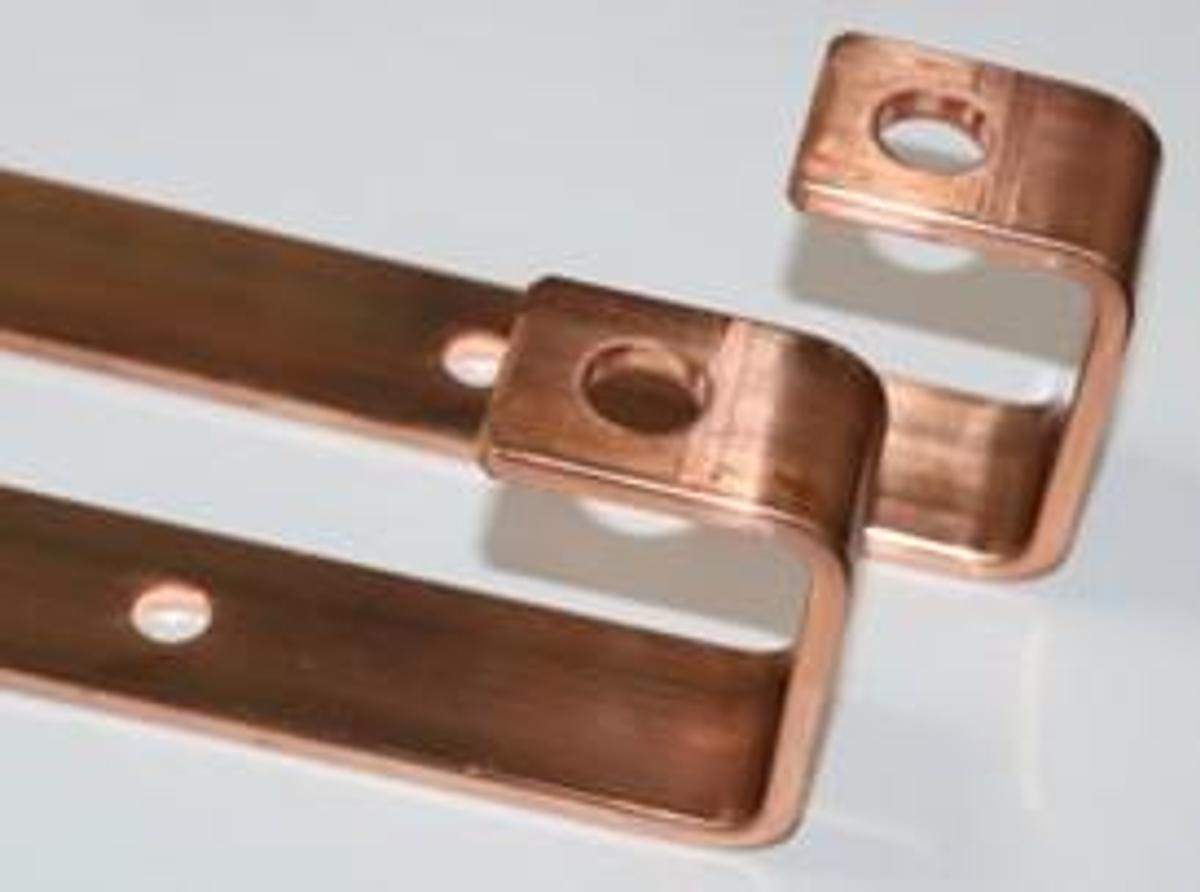

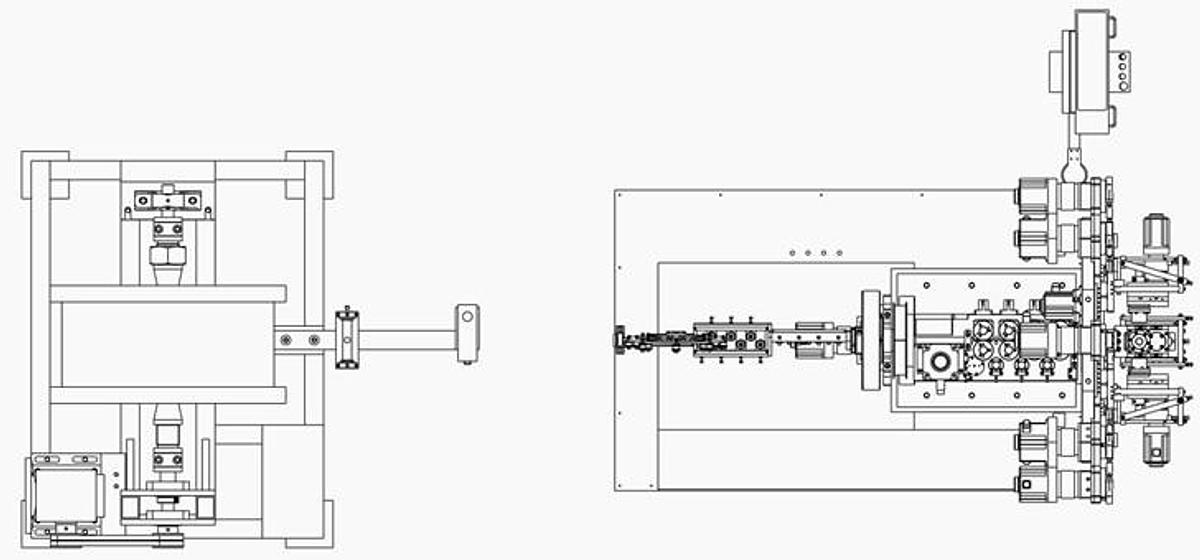

Le Piegatrici punzonatrici curvatrici e taglio a CNC per barre RAME E ALLUMINIO sono uno dei dispositivi più utilizzati nel settore. IBETAMAC mette a disposizione dei suoi clienti una piegatrice per barre in grado di piegare sbarre fino a 50*6 mm. Come sapete le barre devono essere piegate in diverse forme per essere installate sui quadri elettrici e sui quadri elettrici per motivi dai più svariati . Questa serie di macchine per barre è costituita da macchine 3 in 1, il che significa che le barre possono essere completamente lavorate (piegatura, taglio, punzonatura e curvatura torcitura ) su queste dispositivi. La caratteristica più importante di questa serie di macchine per barre è che un operatore può azionare tutte le impostazioni e la macchina produrrà automaticamente 8 assi controllati.

Caratteristiche della macchina

° La macchina è dotata di 8 set di servomotori e ha un'elevata precisione. Può raggiungere una precisione di ± 0,05 mm e la ripetibilità della precisione di lavorazione può raggiungere ±0,02 millimetri. È inoltre dotato di un encoder ad alta precisione per garantire l'accuratezza del pezzo lavorato.

° Questa macchina ha un alto grado di automazione. È dotato di un sistema di controllo CNC, in grado di elaborare con precisione le dimensioni richieste del prodotto e ridurre l'intensità del lavoro dei lavoratori. La macchina è inoltre dotata di una varietà di dispositivi di sicurezza, in grado di prevenire efficacemente qualsiasi potenziale incidente di sicurezza.

° La piegatrice, punzonatura, macchina da taglio per sbarre collettrici in rame è un'attrezzatura molto avanzata con prestazioni eccellenti. Ha un'elevata precisione, una buona stabilità, un alto grado di automazione e una varietà di dispositivi di sicurezza. È adatto per la lavorazione di sbarre collettrici in rame nella produzione di apparecchiature elettriche, nella costruzione di sistemi di alimentazione, nella strumentazione e in altri settori.

Vantaggi della macchina:

Nel mondo dei quadri elettrici e dei quadri di controllo, la precisione e l'efficienza sono fondamentali. Le nostre macchine CNC all'avanguardia offrono una serie di vantaggi che trasformeranno le vostre operazioni di lavorazione delle sbarre:

- Precisione senza pari: Ottenete tagli e punzoni sempre precisi con le nostre macchine CNC, garantendo un'integrazione impeccabile delle sbarre nei vostri assemblaggi elettrici.

- Produttività migliorata: semplifica il flusso di lavoro di produzione con le nostre funzionalità CNC ad alta velocità, riducendo drasticamente i tempi di elaborazione e aumentando l'efficienza complessiva.

- Riduzione dei costi di manodopera: Riduci al minimo i requisiti di manodopera manuale e ottimizza la tua forza lavoro con le nostre soluzioni CNC automatizzate, semplificando le operazioni per una produzione economicamente vantaggiosa.

- Costruzione robusta: le nostre macchine sono costruite per resistere alle esigenze degli ambienti industriali, garantendo anni di prestazioni affidabili e tranquillità.

- Interfaccia intuitiva: il nostro software intuitivo e il pannello di controllo intuitivo rendono il funzionamento un gioco da ragazzi.

Caratteristiche:

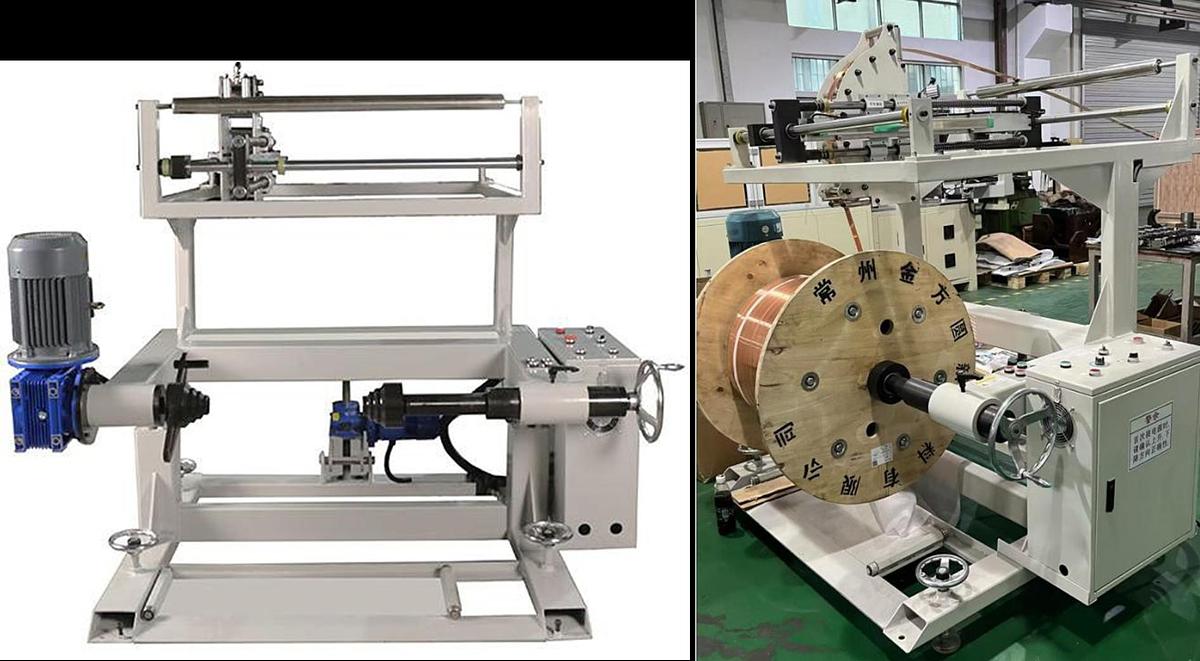

• Adatto sia per filo che per nastro.

• La velocità di avanzamento del filo può essere regolata automaticamente e a impulsi;

• La commutazione di direzione può realizzare l'alimentazione del filo in avanti e indietro e cambiare la direzione di alimentazione del filo;

• Quando il filo è attorcigliato, rotto o l'alimentazione del filo è completata, la macchina emette automaticamente un allarme e si ferma;

• La funzione di fissaggio della bobina può regolare liberamente l'asta di supporto interna sul vassoio e fissare la bobina del filo per evitare che il filo si aggrovigli.

Specifiche

| Produttore | IBETAMAC |

| Modello | IB 50 6 |

| Anno | 2025 |

| Condizione | Nuovo |

| Numero di magazzino | IB 50 6 |

| Gamma di lavorazione minima e massima barre (mm) | da 1 a 6 mm di spessore e da 10 a 50 mm di larghezza |

| Assi controllati | 8 |

| Potenza motore principale (Kw) | 7.5 |

| Dimensioni esterne (WxLxH) | 4000x2000x2200 mm |

| Peso (kg) | 5500 |

| Capacità di taglio (mm) | 50x6 |

| Capacità di piegatura torcitura e curvatura (mm) | 50x6 |